Are you still troubled with packaging problems?

Let’s start with a customer case:

In a luggage factory, the original filling material is filled paper, and it is now replaced with the air cushioning produced by our air packaging machine. It is not only easy to fill, but also makes the bag beautiful and generous.

Cost Analysis:

1, Material cost

Material cost is equivalent to that of filling paper.

2, Labor cost

Customize the corresponding specifications of small air bags for three kinds of bags, one bag and one bag, without pretreatment, filling speed is 3-6 times of the original, saving labor costs.

3, Customer Experience

Domestic consumers: Luggage overall beautiful and generous, high consumer satisfaction, further enhance product image and enterprise competitiveness;

4, Foreign orders

Solve the paperless filling requirements of foreign luggage orders and expand the foreign market.

Packaging Solution:

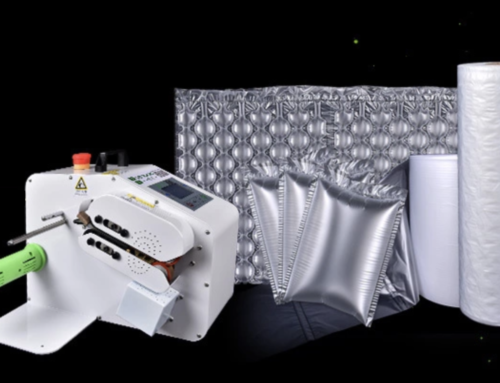

1, Provide air cushion machine and film roll consumables for small air pillows;

2, Customize bubble bag feeding system to produce and store bubble bags in real time, make full use of workshop space and reduce storage area.

3, The worker fills the workstation to realize the pick-up, which is convenient and fast.

Total Consumption of 1 Roll Traditional Bubble Film = 2 Rolls New Bubble Pad = Same Consumption Cost

Comparing with the traditional bubble film, the total consumables for wrapping articles of the same size are half of the traditional bubble film. For manufacturers, it saves production costs, and for customers, it saves logistics costs. So it’s time to consider changing your packaging plan!

What is an air cushion machine?

Buffer air cushion machine is also called air packaging machine, which fills various rolled film, pillow film, bubble film and column film with air. These bubble membranes can be used for filling boxes or wrapping products after inflating. They are mainly used in logistics delivery or factory warehouse delivery, and can be applied to all walks of life.

Buffer air cushion machine can realize automatic inflation process. There are two types of buffer air cushion machines on the market. One is to inflate cushion with valve, and the other is to combine the two functions of inflation and sealing, and it is to inflate cushion without valves.

The air cushion machine can be directly placed on the table top and the assembly line to manufacture air cushion. The air cushion film has three types of film, suitable for different occasions and different products, the cushion effect is excellent. Many factories/companies/e-commerce now use this mini-tool. Buffer air cushion machine can be filled with different specifications of air bubbles, on-demand inflating, saving storage costs, super convenient.

Product Features:

1, Low Cost

The air column packaging bag is composed of 99% air and 1% plastic film. Its packaging material is completely flat before use. It saves a lot of transportation and storage costs without occupying space. Under general conditions of use, the bubber packing air cushion can save you 10% – 30% of the cost.

2, Save Space

The air column inflatable bag product is completely flattened before being inflated, light in weight and small in size, and can be put on the line in real time, filled immediately. It can be put on line in real time and filled immediately. On-demand inflating and does not need to occupy much storage space.

3, Safety

The air column packing bag has excellent support. A single air column packing bag can withstand static pressure of 60-120 kg without breaking. Air column packaging bags can really protect the packed products, not just filling and supporting. Compared with the traditional filler, it will not be damaged caused by the moving of the goods in the process of transportation due to the large gap in the inner box of the package. Even if the external force is squeezed, the close-fitting design of the air column bag can also use the air cushion to disperse the pressure to avoid damage.

4, Recyclable and Non-polluting

The raw materials used in air column inflatable bag products are not toxic substances and toxic heavy metals by authoritative testing, and conform to the European RoHS environmental protection standards. Whether in production, use, placement or recycling, the raw materials (film) or finished products (air cushion) are completely clean, will not cause any pollution, no environmental problems.

5, Reduce Packaging Process and Save Manpower

The air column inflatable bag product uses the special production equipment, which is easy to produce, easy to modify, fast and simple to operation, and has a very short supply cycle.

Why buy our air cushion machine and roll film as your packaging solution?

Our company is a Chinese buffer packaging solution service provider, with advanced industry research results and a large number of practical accumulations, has been committed to buffer packaging equipment, materials and structure research.

CE certified equipment guarantees stable, reliable and continuous production, and abundant energy sources continue to provide cushioning materials for customers everywhere. The modular design makes after-sales problems simple. If your machine has a problem, you only need to replace the broken parts and do not need to buy the whole set of machines again. If a non-modular machine fails, you have to buy a new one. By contrast, you will find that it is obvious that purchasing our machines will greatly save your total cost.

The products and services we provide cover logistics, express delivery, communications, e-commerce, pharmaceuticals, automotive parts, crafts, cosmetics, bags, and many other industries.

Our company is your trusted supplier of cushioning packaging.