What are Packing Air Bags?

“Packaging is AIR.” One person said.

Packaging air bags are new era products of the development of the cushioning protection packaging industry. It is a recyclable and cushioning packaging material, gradually replacing the early waste paper, foam and other packaging materials.

Packaging air bags can be divided into inflatable bubble packaging and air filled packing bags. Air bubble film are commonly used in the shape of gourd balls and small waves. They are used for express delivery and packaging, wrapping products or laying in the box. Isolate the product from the packaging container to prevent the product from being damaged by direct contact with the packaging container.

Air bubble film also called air bubble packaging, air bubble film, bubble packaging, packing air bubbles, packaging bubble, air bubble packaging wrapper, plastic air bubble packaging, air bubble packing material, bubble on demand, bubble film packaging, air bubble film for packaging, air bubble film, air cushioning, packing air cushions, inflatable air cushion, air cushion film, air cushion wrap, air cushion roll, air cushion packing, inflatable air cushion packaging, cushion wrap packaging, air cushion shipping, air cushion film roll, air cushion package.

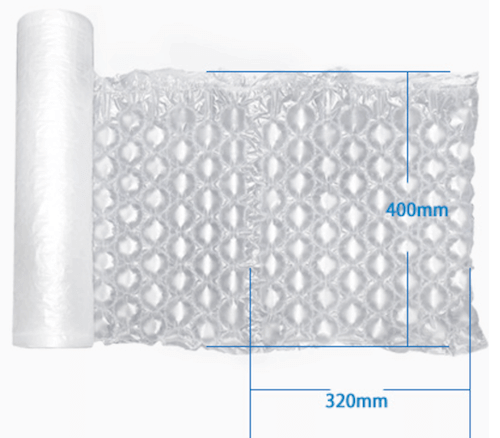

We supply below three best-selling air bubble packaging to protect your goods avoid damage during transportation.

- Air bubble film, HDPE, 40cm x 32cm, 18um / 15um / 30um, 300 meters/roll

- Air bubble film, HDPE, 40cm x 28cm, 18um / 15um / 30um, 300 meters/roll

- Air bubble film, HDPE, 60cm x 40cm, 18um / 15um / 30um, 300 meters/roll

Air pillows also called air pillow film, packaging air pillows, air pillows for shipping, packing air pillows, air filled pillow, shipping pillows, air cushion pillow, air pillow bags, air filled packing pillows, air pillow roll, void fill air pillows, air pouch, air pouch packaging, air pouches for shipping, air cushion bags, air cushion packaging bag, air pad packaging.

Air filled packing bags shape such as air bubble pillow, common specifications are: 200 * 100mm, 200 * 130mm, 200 * 150mm, and 200 * 200mm, used to fill the gap between the packaging container and the product, to prevent the product in transit shake and collide to protect the safe transportation of products.

We provide below popular packaging air pillows for shipping.

- Air pillow packaging, HDPE, 20cm x 10cm, 18um / 15um / 30um, 600 meters/roll

- Air pillow packaging, HDPE, 20cm x 13cm, 18um / 15um / 30um, 600 meters/roll

- Air pillow packaging, HDPE, 20cm x 15cm, 18um / 15um / 30um, 600 meters/roll

- Air pillow packaging, HDPE, 20cm x 20cm, 18um / 15um / 30um, 600 meters/roll

If you want to protect fragile products, such as glass bottles, ceramics, electronics, pharmaceuticals…, you also can consider air column roll (with valves), material is LDPE+15%PA (nylon).

The air column roll is a new air tube packaging that can protect your products perfectly. With the protection of air column wrap, you no need worry about any defective products occurred during shipment.

With air column wrap protecting your products, you can reduce your customer complaints and increase customer satisfaction.

We produce below air column packing with different width for you choice.

Specification:

Air Column Roll (with air valve), LDPE+15%PA, 55um, 300 meter/roll

Width:

- 15cm

- 20cm

- 25cm

- 30cm

- 35cm

- 40cm

- 45cm

- 50cm

- 55cm

If you need custom film thickness and width of air column roll, please contact us.

If you want to protect your products with glass bottles, wine bottles…, our Q shaped air column bags will be the best solution for you.

Q shaped air column bags also called wine bottle protector, inflatable bottle protector, inflatable wine bottle protector, inflatable bottle packaging, protective packaging for glass bottles, inflatable bottle bag, air packaging for wine bottles, wine bottle protector bags, wine wings bottle protector, liquor bottle protectors for travel, wine bottle protector sleeves …, they are all the same products.

We have rich experience in custom Q shaped air column bags for customers around the world.

If you need custom Q shaped air column bags to protect your glass bottles (wine bottles), please contact us.

Except Q shaped air column bags, we also can custom L shaped air column bags and U shaped air column bags as per the dimensions of your products.

Q Type Air Column Bag (Inflatable Air Packaging Bag)

L Type Air Column Cushion Bag

U Type Inflatable Air Column Bag

The customized air column bags will will perfectly protect your product from damage.

Benefits

Air bag packaging is a kind of protective packaging method with stronger protection. It has great advantages over traditional packaging methods. The uninflected space is very small, which can save a lot of storage space for enterprises; and the air bag packaging is very simple and beautiful. Compared with waste paper and foam packaging, the appearance of the package has been improved by N grades, which invisibly increases the market competitiveness of the enterprise products.

How to Use Air-filled Bags?

Air-filled bags are required for protective packaging in many industries. For example, ceramics, glass products, and electronic products are easily damaged due to various impacts during transportation. Therefore, air cushioning protective packaging is required.

Buffer protection packaging is an important part of transport packages and an indispensable part of express transport packages. A good and beautiful package can arouse consumers’ second consumption interest, stimulate other consumers’ consumption and bring better market propaganda for enterprises.

Packaging is usually divided into outer packaging and inner packaging. Outer packaging is an effective way to protect fragile goods from damage. Outer packaging should have certain compressive strength and puncture strength, which can protect fragile goods from damage under normal transportation and storage conditions.

Inner packaging is also called cushioning packaging. Cushioning packaging is mainly to fix and protect the inner products. Air filled bags can protect fragile goods from collision and vibration during transportation, provide cushioning protection, and can protect products in good condition.

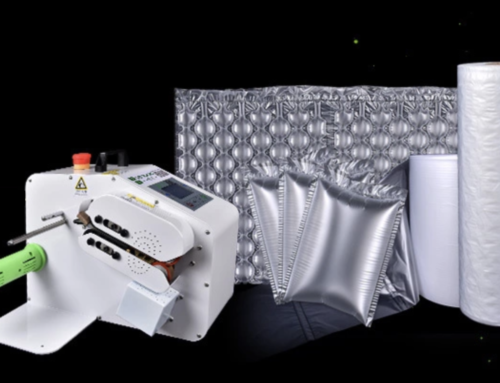

The production of carton air cushion bags needs to be equipped with an air cushion machine. The air cushion film is inflated by air cushion machine to make air-filled bags. It is simple, efficient and easy to use. It can quickly complete the packing task of the day without storage pressure.

Packing air bag is a kind of packaging material used for product transportation protection. The air packaging bags are rolled film before use, and it needs to be inflated before it can be used for product protection packaging. So how do packing air bags inflate? What is the air-filled method of packing air bag?

Inflatable packaging bags are inflated with a special supporting equipment air cushion machine. The air cushion machine can quickly and conveniently make packing air bags, which makes the packing more efficient. The packing air bags inflation only needs to put the air cushion film roll on the device and inflate according to the operation instruction. A large number of packaging air bags can be produced. The air cushion machine has a variety of functional styles, and users can choose according to their own needs.

If the user’s packaging product specifications are uniform, just use a single packing air bag, you can choose mini air cushion machine, the advantages are compact body, simple operation, price concessions, can meet the packaging needs of most small and medium-sized users.

If the user’s packaging products have a wide variety of specifications and need to use wrap and filled air bag packaging, then you can use the air packing machine, fast speed, powerful, stable performance, can make air cushion bags of various specifications to meet the packaging needs of most users.

Air cushion machine also called air bubble machine, bubble packing machine, air bubble packaging machine, air cushion packaging machine, air cushion system, air filled cushioning system, fill air machine, air pillow machine, air pillow packaging machine, air pillow maker, air pillow packing machine, air pouch machine, air pouch packing machine, air pad machine, air pad packaging machine, air fill machine, air packing machine, air pack machine, air packaging machine, air fill packaging machine, inflatable air packaging system, inflatable packaging machine, inflatable packaging system, protective packaging machine, air packaging system, air bag machine, air bag packaging machine, air column bag making machine, packing air bag machine, air bag packing machine, air fill bag machine, airbag packaging system, void fill machine, air void fill machine…, they are the same on demand inflatable air protective packaging machines.

- Air Cushion Machine_#BY-004 (H035)

Watch this video, you will learn how our air cushion machine to inflate air pillows (air pouches), air bubble film, air cushioning… inflatable air cushion packaging film.

The inflation speed of our air cushion machine is up to 28 meters/minute, and the price of this protective inflatable packaging machine is cheap and cost-effective. We sincerely recommend it to you.

- Air Cushion Machine_#Q15

If you want to inflate air column packing like air column roll and air column bags, then the above video will tell you how our air column bag making machine inflate them.

This air cushion machine is an artifact to improve your packaging efficiency and its maximum inflation speed is 15 meters/minute. Highly recommend this air packing machine to you.

How to Use Express Inflatable Packaging Air Bags?

Because the product will encounter external impact and internal extrusion during transportation, which can easily lead to damage during transportation. Therefore, the product needs cushion protection, so you need to use courier packing air bags to ensure safe transportation of products.

Cushioning packaging should be completed according to the product’s performance characteristics and transportation conditions. The most direct method of cushioning protection is to completely wrap the product with packing air bags and fill the air bags between the product and the package to fully cushion all parts of the product.

The inflatable packaging air bags have good pressure resistance and impact resistance, and have strong ductility and is difficult to spray, and its impact on the product is minimized through its tensile and tensile properties.

Packaging air bags have many specifications, which can be selected according to the shape and characteristics of the product. Air cushion bags of different shapes and specifications can be used for 360 degree real protection of each product.

The magical effect of the courier air cushion packaging.

Courier air packing bags can be used not only for product packaging and bedding, but also for filling the gaps in packaging. The air packaging bags have a very light texture that protects the product without increasing the weight of the package. It is the necessary packaging material for transport buffer protection packaging.

If you are experiencing product damage in transit due to improper packaging.

If you are looking for a better supplier of protective packaging materials.

If you are troubled and do not know how to choose inflatable packaging material and air cushion machine.

We are professional an air packing material and air cushion machine manufacturer and supplier in China, and have the ability to be your best protective packaging solution provider.

Our China factory has 15+ years of experience in protective packaging material design and production, and can provide the most suitable inflatable air cushioning material and air packing machine for you.

At the same time, we also accept customized air cushion packaging material and air fill machine.